Kev Cai 99.999% Ultra Purity 5N 300mm Oxygen-free Round/Rectangular/Square Copper Ingot

Loj muaj los ntawm Ruiyuan: 220-400mm, 300mm, 310mm, 350mm thiab ntau yam kev xaiv customized Cov duab muaj los ntawm Tianjin Ruiyuan: puag ncig, square, rectangular, sputtering targets, profile duab thiab qhov ntau thiab tsawg, customized-made

Ruiyuan oxygen free tooj liab yog malleable heev thiab sib xws, excellent nyob rau hauv hluav taws xob thiab thermal conductivity. Cov theem siab purity ntawm oxygen-free tooj liab txhim kho cov yam ntxwv ntawm tus qauv tooj liab khoom, xws li thermal thiab hluav taws xob conductivity, ductility, impact strength, thiab machinability. Vim yog cov zoo no cov khoom, cov khoom siv no yog siv rau hauv ntau yam kev siv industrial. Nws yog zoo heev rau soldering thiab brazing zoo li. Qhov no ua rau nws nyiam ntawm cov hluav taws xob, tsheb, thiab kev sib txuas lus cov kws tshaj lij.

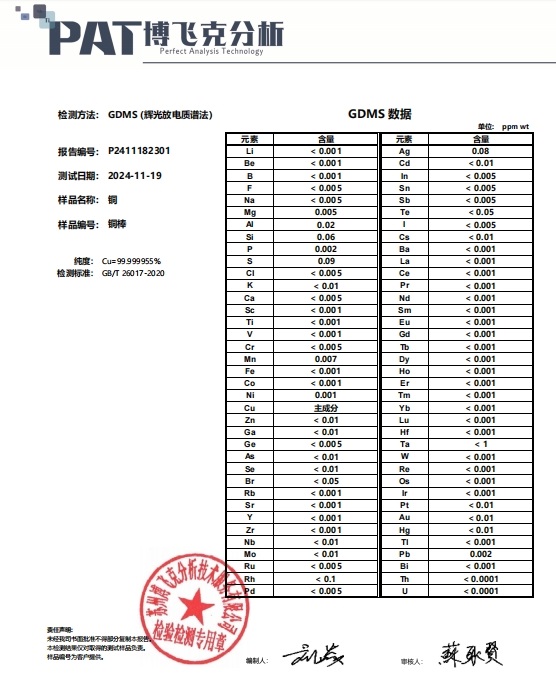

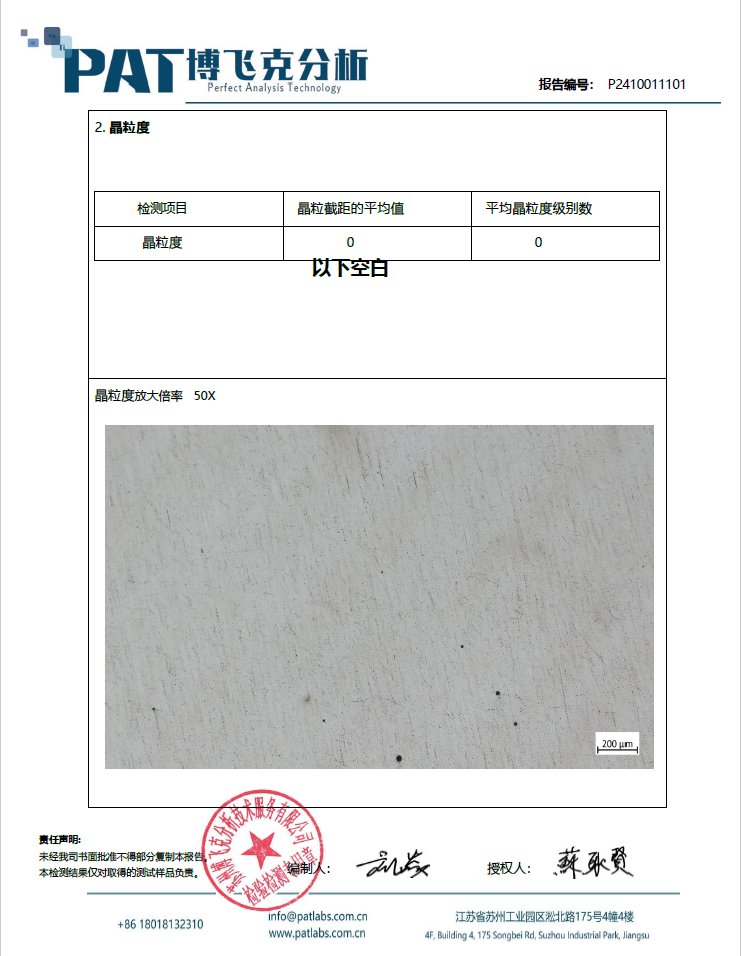

Ruiyuan muaj 100% kev tshuaj xyuas me me thoob plaws hauv tag nrho cov txheej txheem tsim khoom uas lav tias txhua daim ntawm cov khoom siv tau raws li metallographic contamination raws li GB tus qauv uas kuj tuaj yeem ua raws li Chav Kawm 1 lossis Chav Kawm 2 ntawm ASTM. Kev tshuaj xyuas raws li GB / ASTM yog ua rau txhua daim txiav tom qab casting, rau txhua yam khoom tom qab kub deformation lossis nyob rau theem kawg ntawm kev tsim khoom.

Cov Ntaub Ntawv Txog Cov Khoom Siv Tshuaj

| Cov ntsiab lus | O | P | Sb | As | Bi | Cd | Fe | Pb |

| C10100/TU00 | ≤ 5 | ≤ 3 | ≤ 4 | ≤ 5 | ≤ 1 | ≤ 1 | ≤ 10 | ≤ 5 |

| Ruiyuan hlau OFHC | ≤ 1 | ≤ 2 | ≤ 3 | ≤ 1 | ≤ 1 | ≤ 0.5 | ≤ 7 | ≤ 3 |

| Cov ntsiab lus | Mn | Ni | Se | Ag | S | Te | Sn | Zn |

| C10100/TU00 | ≤0.5 | ≤10 | ≤3 | ≤25 | ≤15 | ≤2 | ≤2 | ≤1 |

| Ruiyuan hlau OFHC | ≤0.3 | ≤2 | ≤1 | ≤15 | ≤10 | ≤1 | ≤1 | ≤1 |

Cov Ntaub Ntawv Txog Lub Cev

| Kev chim siab | Lub zog tensile | Kev yoog tau | Qhov nyuaj | |

| O | 195-255 MPa | >35% | <60 HV | |

| 1/4H | 215-275 MPa | >25% | 55-75 HV | |

| 1/2 teev | 245-315 MPa | >15% | 75-90 HV | |

| H | 275-345 MPa | - | 90-105 HV | |

| EH | >315 MPa | - | >100 HV |

Tsim muaj xyoo 2002, Ruiyuan tau ua haujlwm tsim cov hlau tooj liab enamelled tau 20 xyoo. Peb muab cov txheej txheem tsim khoom zoo tshaj plaws thiab cov ntaub ntawv enamel ua ke los tsim cov hlau enameled zoo tshaj plaws. Cov hlau tooj liab enameled yog lub hauv paus ntawm thev naus laus zis uas peb siv txhua hnub - cov khoom siv hluav taws xob, cov tshuab hluav taws xob, cov hloov pauv, cov turbines, cov kauj thiab ntau ntxiv. Niaj hnub no, Ruiyuan muaj lub ntiaj teb los txhawb peb cov neeg koom tes hauv kev lag luam.

Kev Taw Qhia Rau Cov Neeg Siv Khoom, Kev Tsim Kho Tshiab coj ntau tus nqi

RUIYUAN yog ib lub tuam txhab muab kev daws teeb meem, uas xav kom peb ua haujlwm ntau dua ntawm cov xov hlau, cov khoom siv rwb thaiv tsev thiab koj cov ntawv thov.

Ruiyuan muaj keeb kwm ntawm kev tsim kho tshiab, nrog rau kev nce qib hauv cov hlau tooj liab enameled, peb lub tuam txhab tau loj hlob los ntawm kev cog lus tsis hloov pauv rau kev ncaj ncees, kev pabcuam thiab kev teb rau peb cov neeg siv khoom.

Peb tos ntsoov yuav txuas ntxiv loj hlob raws li qhov zoo, kev tsim kho tshiab thiab kev pabcuam.

7-10 hnub Lub sijhawm xa khoom nruab nrab.

90% cov neeg siv khoom European thiab North American. Xws li PTR, ELSIT, STS thiab lwm yam.

95% tus nqi rov qab yuav khoom

99.3% Kev Txaus Siab. Chav Kawm A tus neeg muag khoom tau txheeb xyuas los ntawm cov neeg siv khoom German.