Class180 1.20mmx0.20mm Ultra-thin enameled tiaj tus tooj liab hlau

| Daim Ntawv Qhia Txog Kev Xeem: 1.20mm * 0.20mm AIW Kub Cua Self-bonding Flat Wire | ||||

| Khoom | Cov yam ntxwv | Tus Qauv | Cov txiaj ntsig ntawm kev xeem | |

| 1 | Qhov tsos | Kev Sib Luag Zoo | Kev Sib Luag Zoo | |

| 2 | Tus neeg xyuas pib txoj kab uas hla (hli) | Dav | 1.20 ± 0.060 | 1.195 |

| Qhov tuab | 0.20 ± 0.009 | 0.197 | ||

| 3 | Thickness ntawm Rwb Thaiv Tsev (hli) | Dav | Yam tsawg kawg nkaus 0.010 | 0.041 |

| Qhov tuab | Yam tsawg kawg nkaus 0.010 | 0.035 | ||

| 4 | Tag Nrho Txoj Kab uas hla (hli) | Dav | Max.1.250 | 1.236 |

| Qhov tuab | Max.0.240 | 0.232 | ||

| 5 | Kev sib txuas tau 390 ℃ 5S | Smooth tsis muaj draf | OK | |

| 6 | Qhov (pcs/m) | Qhov siab tshaj plaws ≤3 | 0 | |

| 7 | Kev ntev (%) | Yam tsawg kawg nkaus ≥30% | 40 | |

| 8 | Kev Ywj Pheej thiab Kev Ua Raws Li | Tsis muaj qhov tawg | Tsis muaj qhov tawg | |

| 9 | Tus neeg xyuas pib tsis kam (Ω/km ntawm 20 ℃) | Qhov siab tshaj plaws 79.72 | 74.21 | |

| 10 | Lub zog tawg (kv) | Yam tsawg kawg nkaus 0.70 | 2.00 | |

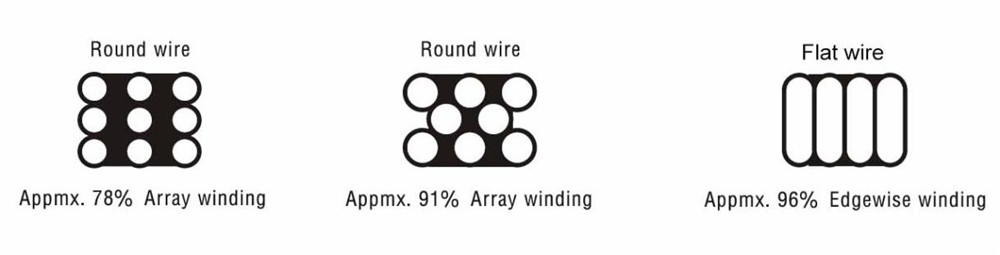

1. Siv ib lub ntim me dua

Cov hlau enameled tiaj tus siv qhov chaw tsawg dua li cov hlau enameled puag ncig, uas tuaj yeem txuag tau 9-12% ntawm qhov chaw, thiab cov khoom siv hluav taws xob thiab hluav taws xob me dua thiab sib dua yuav raug cuam tshuam tsawg dua los ntawm qhov ntim ntawm lub kauj.

2. Qhov chaw siab tshaj plaws

Nyob rau hauv tib qho chaw winding, qhov chaw factor ntawm lub tiaj tus enameled hlau tuaj yeem ncav cuag ntau dua 95%, uas daws qhov teeb meem bottleneck ntawm coil kev ua tau zoo, ua rau qhov tsis kam me dua thiab lub capacitance loj dua, thiab ua tau raws li qhov yuav tsum tau ua ntawm capacitance loj thiab cov xwm txheej thov siab.

3. Thaj chaw hla loj dua

Piv nrog rau cov hlau enameled puag ncig, cov hlau enameled tiaj tus muaj thaj tsam loj dua, thiab nws thaj chaw cua sov kuj nce ntxiv raws li, cov nyhuv cua sov tau zoo dua, thiab "cov nyhuv ntawm daim tawv nqaij" kuj tuaj yeem txhim kho tau zoo heev (thaum lub zog hloov pauv hla tus neeg xyuas pib, tam sim no yuav raug sib sau ua ke hauv tus neeg xyuas pib. Qhov chaw ntawm tus neeg xyuas pib ntws los ntawm), txo qhov poob ntawm lub cev muaj zog siab.

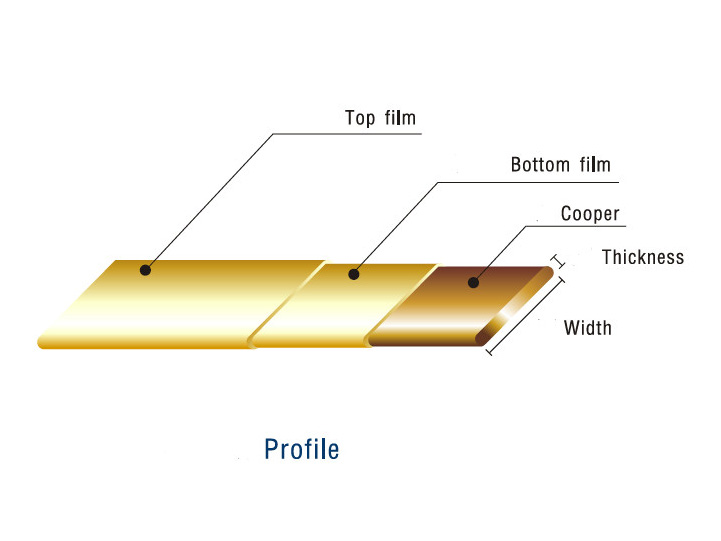

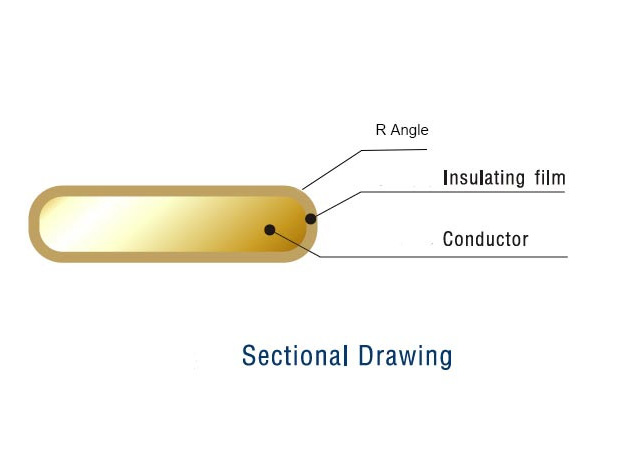

• Qhov loj ntawm tus neeg xyuas pib yog qhov tseeb siab

• Cov khoom rwb thaiv tsev yog coated uniformly thiab nplaum. Cov khoom rwb thaiv tsev zoo thiab withstand voltage yog ntau tshaj 100V

• Cov khoom siv winding thiab bending zoo. Kev ntev yog ntau tshaj 30%

• Tiv taus hluav taws xob zoo thiab tiv taus cua sov, chav kawm kub tuaj yeem ncav cuag txog li 240 ℃

• Peb muaj ntau hom thiab qhov loj ntawm cov hlau tiaj tiaj uas sib txuas tau thiab sib txuas tau, nrog rau lub sijhawm xa khoom luv luv thiab MOQ qis.

•Inductor •Lub cev muaj zog •Transformer

• Lub Tshuab Hluav Taws Xob • Lub Suab Coil • Lub Solenoid Valve

5G Chaw Nres Tsheb Fais Fab

Kev tsav dav hlau

Tsheb ciav hlau Maglev

Cov Turbines Cua

Tsheb Tshiab Zog

Khoom siv hluav taws xob

Peb tsim cov hlau tooj liab enaemeled rectangular hauv cov chav kawm kub 155 ° C-240 ° C.

-Tsis tshua muaj MOQ

-Kev xa khoom sai

-Zoo Tshaj Plaws

Ruiyuan nyiam ntau tus neeg txawj ntse thiab kev tswj hwm zoo heev, thiab peb cov neeg tsim tsa tau tsim pab pawg zoo tshaj plaws hauv kev lag luam nrog peb lub zeem muag ntev. Peb hwm txhua tus neeg ua haujlwm tus nqi thiab muab rau lawv lub platform los ua Ruiyuan qhov chaw zoo rau kev loj hlob hauv kev ua haujlwm.